Some tech tips to help you choose the right wheel.

Generally speaking, a carbon rim is lighter compared to an aluminum rim of equivalent strength, and has a longer life cycle. Given the same weight, a carbon rim is far stronger and durable than an aluminum rim. There’s a general consensus on this. Some think carbon rims are too stiff… it’s not true, depending on the section and lamination, they can be very pleasant to ride.

Thanks to the reduced increment on wheelset weight, carbon rims are often wider than aluminum rims, that are usually made narrow to keep the weight down. In addition, carbon rims are not subject to corrosion (caused by latex with ammonia or galvanic corrosion caused by salt water on winter roads). Of course the carbon rim is more expensive and so if you damage it, the economic impact is greater (but our crash replacement policy will help.

Are carbon rims easily damaged? No, but it also depends on what type of user you are. If you like an ultra-light cross-country wheel and then you go all the way down rocky paths with very low pressure and without the slightest care of the trajectories (impacting rocks at speeds that completely crush the tire), carbon wheels are not for you . Not even aluminum ones, to be honest, but at least the replacement of the damaged rim will be cheaper. And, indeed, if you regularly bend aluminum rims, carbon is probably not for you.

Now that disc brakes are standard, aluminum rims only have one benefit: the lower cost (compared to carbon), thus reduced concern for damage. Many believe that if an aluminum rim flange is bent, it can be straightened and reused in safety; the first part is often true, the second maybe not, even if it is probably impossible to determine the extent of the risk.

Many carbon rims are now hookless, meaning the flanges are straight, without hook. This allows manufacturers to make stronger flanges with lower production costs. But is it safe? Only if using tubeless / tubeless ready tires. In traditional rims, in fact, the inner tube pushes the bead of the tire under the hook preventing a blow off, as Jobs Brandt explained in his famous book “the bicycle wheel”, so much so that he suggested to do this test: cut the bead vertically at one point and inflate the inner tube, the bead will remain in place (despite the discontinuity of the fiber that runs through it) because the inner tube pushes it and holds it under the hook (we take his word for it, never actually did this test!).

On hookless rims the bead remains in position when inflating only thanks to the longitudinal fiber in it, which ensures the safety of the setup. Same that happens with car tires. And tubeless tires have different fibers (low elongation/high strength) in the bead and are built with better tolerances, to avoid tire blowouts towards the outside (and also towards the inside). So – let’s say it again – hookless rims are great but only and exclusively with tubeless or tubeless ready tires, even if using inner tubes.

On this particular matter opinions differ, for many reasons. To begin with, tire pressure is related to many factors such as the weight of the MTBiker + bike, the width of the tire channel of the rim (see dedicated chapter), the section and the structure of the tire used (lightweight, normal, reinforced), the type of terrain, the ability to avoid extreme rock impacts, the type of frame (rigid, front, full) and so on.

On rolling resistance there is some confusion and false beliefs, and to shed some light we recommend reading the best work we’ve seen on this matter, on the Silca.cc blog. (Silca is now owned by Joshua Poertner, a person of great talent, experience and competence, former technical director of Zipp).

We can also recommend this video that relates the section of the tires with the rolling resistance: https://www.youtube.com/watch?time_continue=9&v=fGv329v8-vI

Lower pressures offers better control, precision, traction, braking and low rolling resistance, but the rim must be sufficiently wide, otherwise the rollover effect makes the bike unstable/unpleasant to ride and prone to burping. Things also change from tire to tire. For example, I weigh 95kg and I get comfortable with 1.2 / 1.3 bar on 2.2″ “protection” tires and i27 rims (obviously!); some fellow riders think it’s impossible, others confirm using even lower pressures (being lighter).

The important thing to consider is the “tension” of the tire, because as the section of the tire increases, the pressure must be lowered to keep the tire tension the same. Furthermore, it would be correct to consider the actual section, which is obtained (approximately) measuring the circumference of the tire minus 10mm plus channel width.

Certainly, the tire protects the rim from impacts on hard rocks, so with lower pressure there’s less protection. Moreover, as mentioned, with low pressures a “loose” tire can burp.

So, if you want to start riding with lower pressures, how do you do it? If the tire is tight enough, you can start to reduce one PSI (or 0,1 bar) at each new ride, and see how you like it, nothing is better than the individual riding sensations. When riding ceases to improve and starts getting worse, you can go back one step.

The non-governmental body that norms size and compatibility of rims and tires, is called the European Tire Rim Technical Organization. It is an organization where the “weight” of tire manufacturers is enormously superior to the “weight” of wheel manufacturers. (www.etrto.org). However, from 2019 the matter will be regulated by ISO (which will use the ETRTO data).

So, what is “fatigue” and why is there little talk about it? There are many explanations available online, but if there is any doubt, please let us know, since with composites fatigue is a bit different. There’s probably some reluctance to discuss it, because the idea that parts cannot last forever could be perceived negatively.

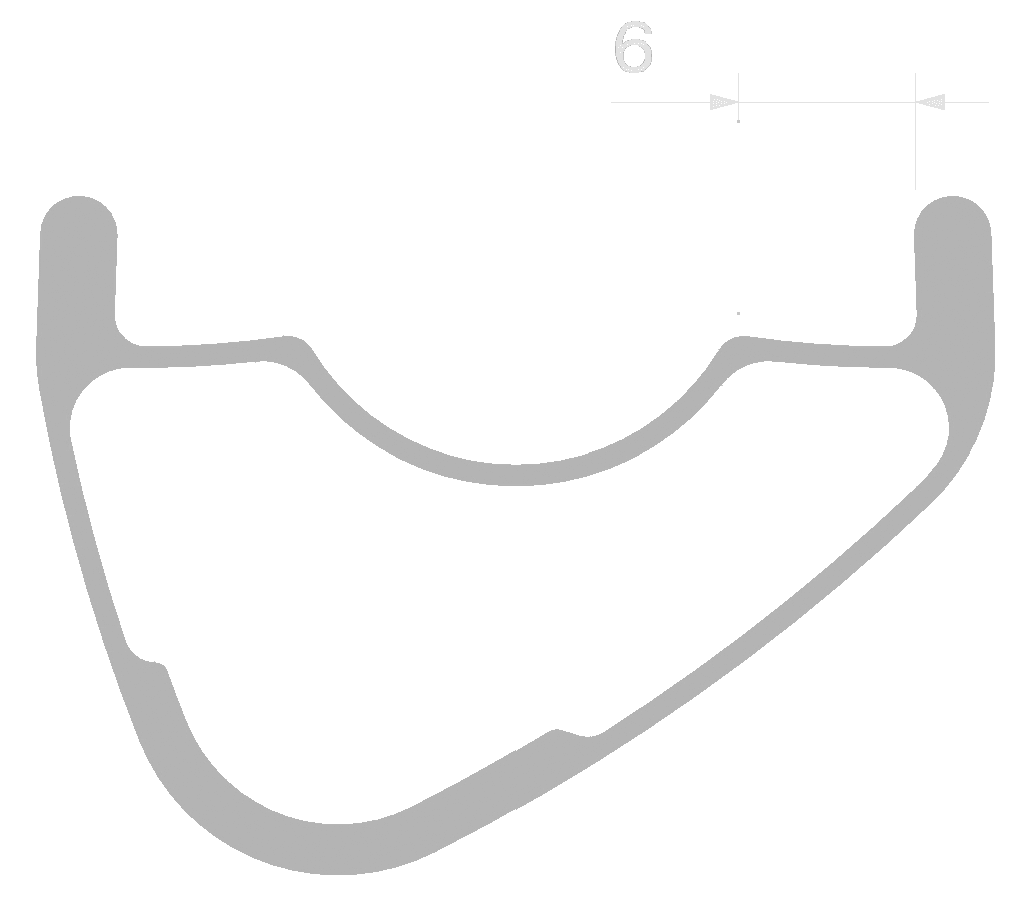

Until recently asymmetric rims were not widely used, why? After all it was already clear twenty years ago that the asymmetry of the rim offered certain benefits (think of Campy’s Neutron or Hyperon)… The reason is simple, there was a patent by Mr. Jiri Krampera and those who wanted to make asymmetric rims had to ask for a license. Most companies preferred not to pay (even if this prevented them from making a superior product) and so, until the patent expired a few years ago, asymmetric rims were rare.

Then there was the issue of the rim width, a narrow rim typically allows a minimal asymmetry, while the more recent wide rims allow for more significant asymmetries.

But why make a wheel with an asymmetric rim? To increase the spoke bracing angle of the disc side in the front and of the drive side in the rear, balancing spoke tension, making the wheels symmetric in terms of lateral stiffness and strength, so that they have no weak side and are more precise and predictable.

A 29” rear wheel with a traditional symmetric rim has nearly vertical freewheel side spokes with much higher tensions compared to disc-side ones; also, the lateral stiffness is very different if the wheel is pushed sideways. Same happens with a front disc brake wheel. Finally, the ultimate resistance of the wheel is very different, and counterclockwise nose press can damage a traditional wheel more easily, as well as an angular impact in a fast descent.

But with the rim asymmetry don’t you reduce spoke bracing angles in the rear-left and front-right? Yes, of course, but we think it is better to have a wheel with the same angles on both sides than a wheel with different angles and one side with low tensions and the other with high tensions and unfavorable angles.

But doesn’t Boost address these issues? We’ll talk about it in the dedicated chapter.

There’s not yet a general consensus on the significant benefits of the wide tire channel for XC, some are still not sold about it. On the other hand, also the 29” wheels were not initially appreciated by everybody. What we have seen is that most of those who believe that a i27 rim like our MP1 is too large for XC, either have never used it, or were influenced by someone that didn’t. Of course the tire size plays a role too (and also on the size of the tires there is a lot to say).

Widening the tire channel, slightly changes the shape of the tire increasing traction, minimizing the annoying roll over, allowing lower pressures and offering greater control and precision. And rolling resistance? The general feeling is that, with the same tire, will increase with the width of the channel, because of the wider footprint, but we don’t ride in velodromes and we address this in the tire pressure chapter.

Also, a wide rim allows bigger asymmetries compared to narrow rims. Defects of the wide channel? Higher weight (which some offset by using a smaller section tire). Also, a wider rim is more vulnerable because it is less protected by the tire. But truth is, once you try wide, you don’t go back to narrow!

Boost was originally conceived to improve spoke bracing angles on 29” wheel. The boost hub is 6mm wider (OLD) in the rear and 10mm wider in the front, has the flanges moved outwards (3mm at the back, 5mm at the front), as well as the brake rotor and the sprockets, so it requires wider stays and forks.

The increased chain line paired with single chainring cranks offers more tire clearance. For example, it is useful for frames that are at the same time 29 “and 27.5” PLUS. Was it worth changing the 100/142mm standard? Perhaps. Could we live without, using asymmetric rims? Possibly. The most critical spoke bracing angle, the sprocket side in the rear hub, is improved by the boost by 3mm, just like a 3mm asymmetric rim, which moreover reduces the unbalance between the spoke tension, without making any changes to the frame or creating new standards.

A rim with an asymmetry of 6m is even better, with symmetric spoke bracing angles and even spoke tensions. But what happens when a 6mm asymmetrical rim is paired with a boost hub? You get a wheel with the widest symmetric bracing angles AND even tensions. Defects? Really minor. The stays widen slightly, and since the Q-factor remains unchanged, there may be greater risk of heel interference. In addition, the boost hubs are slightly heavier than the equivalent non-boost.

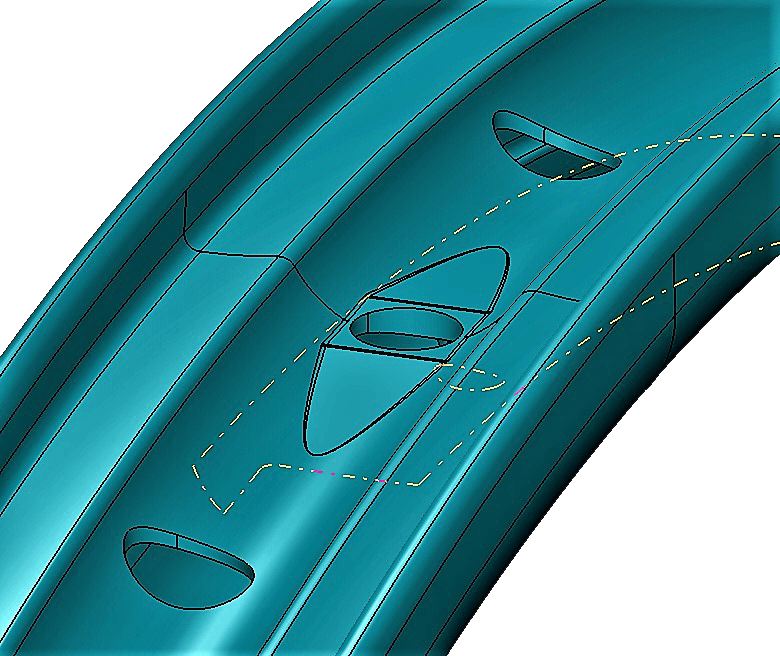

Most of the rims in the market are drilled radially and that’s it. It’s simpler, faster and cheaper. So, why would you drill them double-angle? What does it mean? The double-angle drilling simply means that the hole is aligned with the direction of the spoke. So instead of being radial, it follows both the dish angle and the hub tangency angle of the spoke, minimizing bends and tensions on the rim and nipple, offering a more stable, rigid and long-lasting wheel.

Did we invent it? No, Campagnolo was already doing it 25 years ago. But why doesn’t everybody do it? Because it’s a complication and an additional cost. But we refined the concept further with the D.A.D.O. drilling, double angle double offset, which we consider the best technical solution.

They do! And not just for the weight, more obvious feature. All the other characteristics of the wheel being equal, and leaving out the alteration of the mechanical characteristics of the material itself due to the production process, a bigger section spoke stretches less than a thin one, making the wheel more rigid.

Generally speaking, the characteristics of a complete wheel are the result of the combination of the characteristics of the rim, those of the spokes (section, angle, working in a straight line or bent) and those of the hubs. A wider bracing angle, for example, allows you to use lighter spokes without sacrificing stiffness and lateral resistance of the wheel.

The issue is debated when discussing MTB wheels. Some consider aero spokes useless on a MTB wheel, and from a cost perspective this makes sense. However aero spokes are widely used on hi-end MTB wheels, for good reasons. One thing is that during wheel building, when spokes are tensioned, they must be held still, otherwise they wind up. These torsion aren’t good for the life cycle of the spoke. Holding still an aero spoke is easy and within everyone’s reach, with a round double butted ultrathin spoke, it is more difficult. To prevent winding up, it is necessary to pinch it tightly when the nipple is turned, but without damaging it, as a steel plier would. Not having control over who, over the life of the wheel, will perform service, an aero spoke greatly reduces the chances of making service mistakes. The second reason, and a comparison between CX-Ray and Laser (same weight, one drawn and pressed, the other just drawn) helps clarifying, is that the CX-Ray is superior for mechanical characteristics and fatigue life compared to the Laser. Are these differences perceptible in common use? Probably not (except durability).

Have a look at what Sapim says about their spokes in terms of performance, fatigue life but also wheelbuilding issues at sapim.eu

The third reason, far from trivial but often not considered, is that if a small branch goes between the spokes, the aero spoke has better chances to cut it without bending. The aerodynamic issue is probably negligible in MTB races, besides, we miss hard data.

You always hear about lateral stiffness but almost never hear of lateral strength. In contrast to road racing bikes, MTB wheels are often subject to strong lateral thrusts, for example when on a fast descent the wheel receives a side impact from a rock or a root or something else pushing it sideways. These forces, especially with heavy or fast bikers, subject the wheels to a level of mechanical stress that can overcome the elastic deformation of the wheel.

The 6mm asymmetry of the Palindrom MP1 rims considerably increases the lateral resistance of the unfavorable side of the wheels, harmonizing it with the one of the favorable side, so not only the wheel’s behavior is substantially symmetrical, but also its resistance.

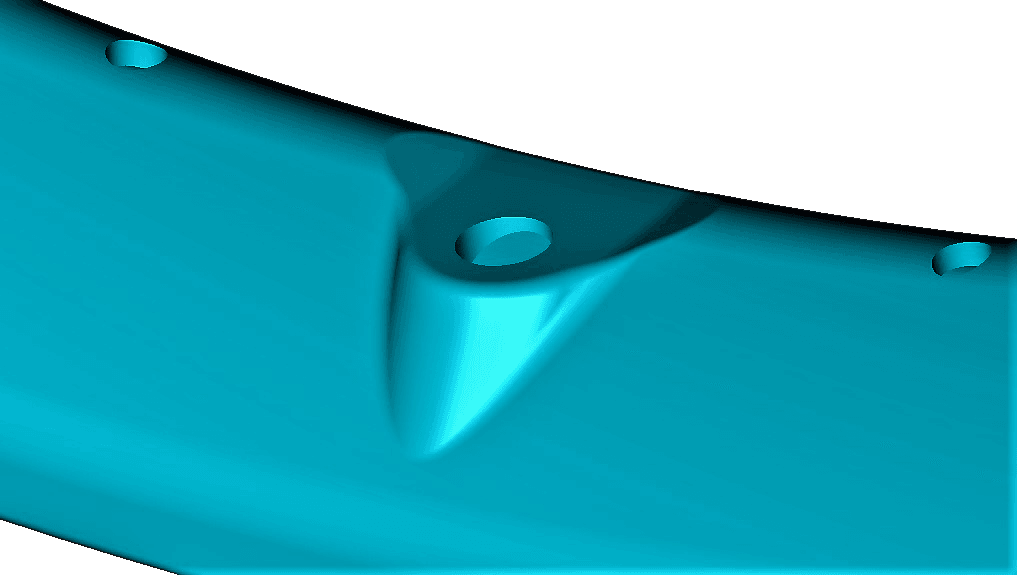

The valve hole and in particular the quality of the seal between the tubeless valve and the perimeter of the hole on the rim is the most frequent cause of pressure and sealing liquid loss. This is because quite often the shape of the valve rubber does not match the shape of the surface around the holes, which are normally made on the curved surface of the channel.

In the Palindrom rims you will not find a normal valve hole but a perfectly circular hole on a perfectly flat surface (photo A) to maximize the sealing quality of valves with flat or conical rubber. In addition, the knurled nut that keeps the rubber part pressed against the channel, also rests on a flat surface (photo B) in order not to induce anomalous tensions.

The tubeless friendly channel has two Interesting features. The first is that the shelf where the tire bead sits is quite wide, 6mm, to minimize burping and the risk of internal blow off with low pressures, the second is that the bead is held in position by the counter-angle of the shelf. Bead seating is more progressive with a less violent impact against the flange and adhesion of the tubeless tapes is improved.

High Modulus carbon fiber makes the rim more brittle, so unfit for MTB use. Unless… the fiber is also high strength, so not only stiffer but proportionally higher in tensile strength. And obviously far more expensive. It is therefore important to find the right balance between the various characteristics of the fiber, with impact resistance resin playing a very important role.

When two different metals like stainless steel and aluminum (spoke-nipple or spoke-hub) are in contact in a humid environment, a galvanic current corrodes the “less noble” of the two metals, the aluminum. It is a frequent occurrence if the wheels are used in wet conditions, worst of all if they are used on salty winter roads. Tubeless sealants containing ammonia are corrosive too if they get inside the rims. For most users corrosion is not common, but in the worst scenarios it is preferable to use brass nipples, that minimize the problem, but add about 35g to the wheelset.